Supply Chain Capacity and Visibility

It is critical to understand a suppliers plant

Understanding a plant is different to understanding the supplier, particularly when the plant is part of a much larger global conglomerate. Whilst much of this information can be obtained from published information on the web for small to medium sized suppliers who only have one plant, much of it cannot. This is particularly true if a suppliers future order book is full (no capacity) or very underutilised (leading to inability to ramp up quickly). The A4 tool is designed to capture key information and, in Hermetica's opinion, should be collected at least once a quarter by anyone who visits the plant (whether that be purchasing, engineering, quality or whoever).

Identifying opportunities in the value stream

Muda, the famous (in lean circles) Japanese term for waste. Pioneered by Toyota, and extended by many to address most value chains, techniques to identify and eliminate waste have become plentiful. If cost is to be eliminated, it can be very useful to apply these techniques, with the essential input of cross-functional teams , to identify opportunities to take out cost.

The techniques can be adapted to most problems

Hermetica has applied variants of this technique to whole industry supply chains (upstream oil & gas), IT services and hardware, and social care services.

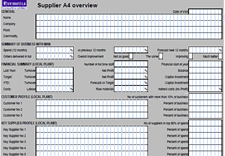

A4 tool to obtain key information about a supplier plant

On the basis it is more important to get key information frequently rather than lots of information irregularly, this single A4 sheet has been designed. It is based on a combination of lean thinking, Read a Plant Fast & Rapid Plant Assessment

Brown Paper Process Mapping

Brown paper mapping is a technique which can be used independently or as part of Value Stream Mapping to identify waste and opportunities in the supply chain. Hermetica has applied a mix of this technique and Value Stream Mapping often.

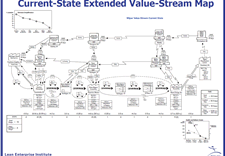

Value Stream Mapping of the Whole Supply Chain

In 2003, Jones and Womak published "Seeing the Whole" which extended Value Stream Mapping to the whole supply chain. This provides a structured technique for analysing waste and identifying opportunities in some detail.